Wow! It’s been a long time since our last blog and the crews have been busy traveling the country, again working on some of the largest power transformers ever manufactured. From North to South and East to West the crews have completed multiple forensic teardowns, large decommissioning projects and time sensitive transformer removals.

We started our summer off with a large forensic project. We have seen a significant increase in the need for root cause failure analysis and our specialized equipment has proven to be extremely valuable to our customers in being able to provide the most detailed teardown, on-site.

Check out this transformer that weighed nearly 800,000 pounds.

This transformer had a premature failure and it was extremely important that our customer and their consultant be able to witness every aspect during the removal of the transformer’s core components.

Once the transformer was opened up the top yoke was removed and windings were carefully sectioned out by phase in order to support a meticulous examination.

A-Line provided engineering the opportunity to investigate potential failures at every step of the process.

This removal was completed in 5 days leaving our customer with the information to close out their root cause failure analysis and also leaving them with a clean site.

The end of summer brought us to some of the largest power transformers ever manufactured and the project proved to be another challenge that A-Line took head on. After draining about 75,000 gallons of oil our crew headed to the southwest to take on these beasts totaling 2.5 Million pounds.

The A-Line team worked systematically to strip these transformers, open them up and load out a significant amount of material in record time. It takes extensive training and teamwork to work safely and efficiently and these guys perform to the highest standards no matter the size of the job.

With our patented equipment, A-Line E.D.S. is able to safely remove hundreds of thousands of pounds of transformer core steel in a third of the time of our competitors, allowing us to provide competitive pricing and minimizing safety hazards and time spent on site. Check out these massive windings after the core steel was removed.

The project was completed in 3 weeks’ time, which equates to removing over 150,000 pounds of transformer material per day. This project certainly kept our recycling facility on its toes.

The site was left clean and ready in preparation for additional construction for the replacement transformers.

While we like to celebrate each project as a new victory there is little time as it seems it’s always on to the next challenge. This next transformer removal was just that, a BIG challenge. While sometimes we have the luxury of wide open spaces this 575,000 pound power transformer recycling project didn’t provide us any such luxury. You can see that maneuvering at this site required skill, teamwork and creative methods that we love to showcase to help our customers save money and get the job done on time.

Our crew took special care in removing radiators, bushings and prepping the tank to open this transformer up.

One thing about large power transformer recycling service is that our projects are like snowflakes- no two are the same. This was especially true for this one. This transformer proved to test our abilities to adapt to the situation based on the location and extremely sturdy transformer design. Very few transformers were made like this one and we’ll give a special shout out to those that were involved in its design and manufacturing because it was certainly built to last.

A-Line E.D.S. worked diligently to remove and load out all the components in record time, in order to provide our customer the pad for reconstruction and placement of the new transformer.

While one of our crews finished up down south another got ready for a Midwest project. We were able to make quick work of this failed transformer weighing in around 370,000 pounds. We were able to decommission this unit and remove an additional 10 units which brought the total to about 550,000 pounds in just 5 days.

A-Line E.D.S. always operates safety when handling each and every transformer component. Our team works flawlessly together to ensure everyone’s safety and attention to protecting our customer’s site.

Once the transformer tank was removed and the core was exposed the failure area in the winding was evident. While we weren’t asked to provide a root cause failure analysis this time, we did provide our customer with photo documentation for their records.

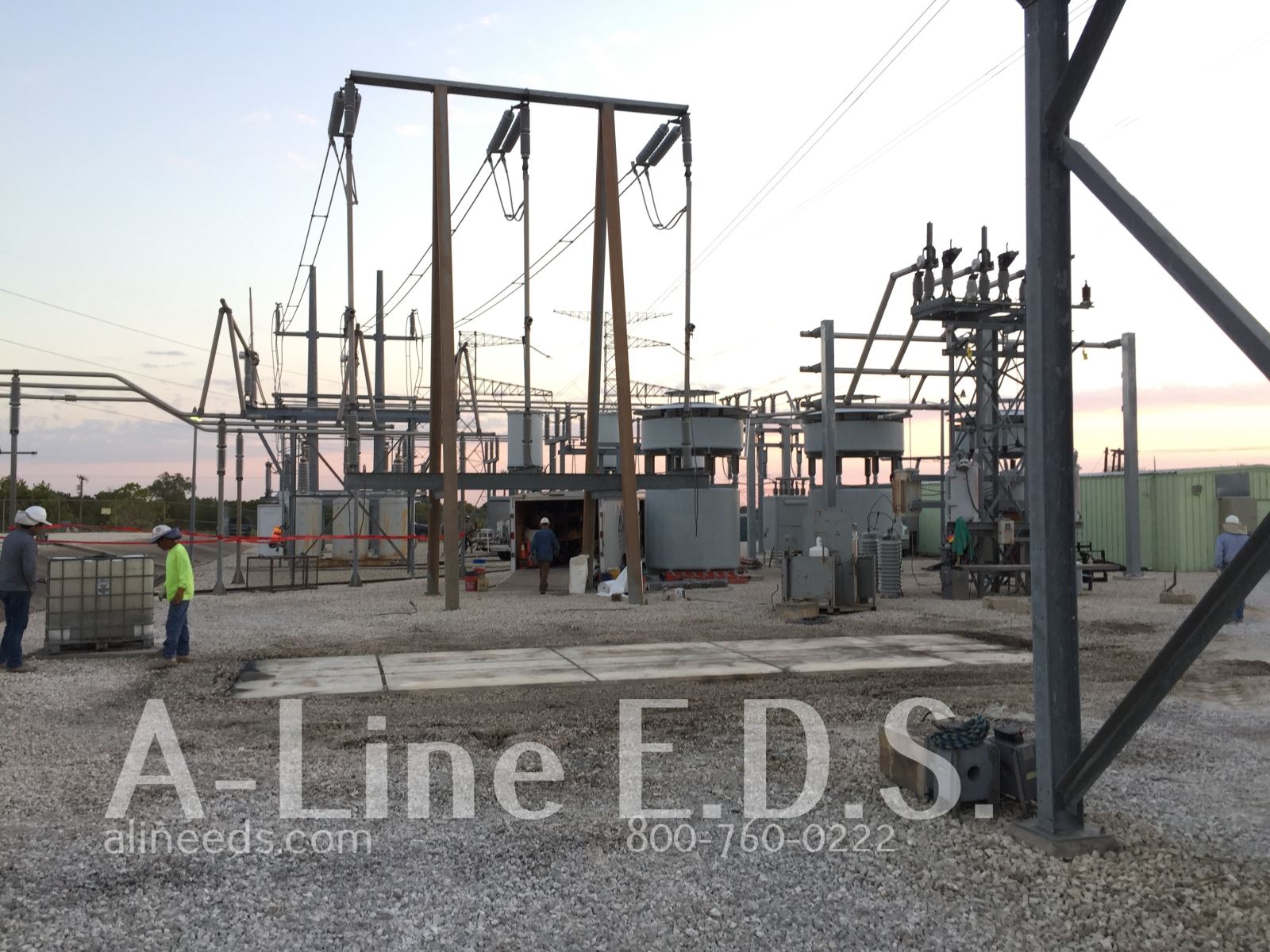

Here is a little overview of our jobsite showing the nature of our operations and our attention to organization and housekeeping.

We always try to leave the site better than we found it and ready for what’s to come.

We appreciate you reading our blog. A-Line E.D.S. truly treats each transformer recycling project personally which has proven to make us the best in the country at what we do. From root cause failure analysis of power transformers to time sensitive transformer recycling projects during upgrade outages, we have the crews, equipment and environmental recycling abilities and permits to meet and exceed our customer’s expectations every time. If we can’t do it, it can’t be done.